Lightening loads with warehouse ergonomics

How companies are using ergonomics to retain employees, minimize musculoskeletal injuries and get a bit more output out of every shift.

In a business environment where jobless claims are the lowest they’ve been in 53 years, the Great Resignation is still in full effect, and the national unemployment rate was 3.6% in March, keeping workers comfortable, safe and productive has become table stakes for most companies. For the warehousing, distribution and logistics sectors — where long shifts and heavy lifting are fairly common — ergonomics are especially important.

Keep the Work Moving

Metal fabrication with ergonomics in mind

Workers are aging. The number of workers older than 45 has doubled since 1950, and the number of people 75 and older in the labor force is expected to grow by more than 96% by 2030. Sometimes because they want to, other times because they have to, people are working longer.

The effects of aging include loss of muscle mass, loss of upper body strength, and lower ability to move and handle loads. Also, about a third of the U.S. population is obese. With that comes greater potential for high blood pressure and arthritis. All this becomes a problem when a fabricator must deal with a significant amount of manual material handling.

Good News for Ergo

A 'landmark event' marks growing industry interest in ergonomics

Twenty years ago, ergonomics "was kind of a nice thing to do," said Jim Galante, chair of MHI’s Ergonomic Assist Systems & Equipment (EASE) Industry Group, but it was not an area that attracted close attention in material handling. In the decades since then, however, he said an aging workforce, increased obesity, rising workman’s comp costs and growing market pressure to do more with fewer people has greatly altered that perspective.

"People talked about it, but for the most part they weren’t paying much attention to it and why it’s important," said Galante, director of business development for MHI member Southworth Products. "A lot has changed since then. Most companies today are taking a proactive look at the ergonomic conditions—or lack of them—in their facilities."

Now comes what experts say could be a watershed moment in the field of ergonomics. Amazon earlier this year announced the rolling out of its WorkingWell safety and injury prevention program to its U.S. sites in 2021. The $300 million program is designed to cut workplace recordable incident rates by 50% by 2025. The program’s emphasis on ergonomics-related injuries could have a widespread impact.

Giving Workers a Productivity Lift

With pressure to increase output from an aging workforce, work access lifts have become much more than just ergonomic aids: they are essential productivity drivers across the large assembly industry.

Assembling any complex product can often become an especially labor-intensive—not to mention callisthenic—activity.

Whether that product is something as relatively small as a skid steer or as massive as an aircraft wing, the assembly job will often require any single worker to crawl on hands and knees, fetch and climb ladders, and continuously reach far past ergonomic guidelines to access each part of the build. As they do this, they must also regularly stop work to retrieve materials and instructions for the job.

By some estimates, all this repositioning, fetching, and stretching can account for as much as 20% of the total labor time.

Material Handling Equipment Makers Focus on Flexibility

Southworth’s Jim Galante discusses how the industry is responding to demands for customized solutions on shorter lead times.

The material handling equipment market is on the move. Manufacturers are churning out new equipment to keep pace with increasing demand as warehouses and distribution centers try to adapt to a constantly changing and more demanding market.

The global market is expected to reach $41.2 billion by 2025, at a CAGR of 6.8%, according to a study conducted by Grand View Research Inc. Another study by Global Market Insights attributes industry growth to increasing demand for automated solutions as organizations grapple with rising labor costs in the material handling segment.

Pallet Pleasers: Ergonomic Solutions Increase Productivity

Lifts, tilters, and turntables can help organizations of all sizes keep pace with modern warehousing demands.

Retail giants like Walmart and Amazon are known for their high-tech distribution centers. These facilities may utilize automated conveying systems and even some robotics that move material. For smaller organizations, investing in such sophisticated equipment may not be an easy decision or it is just economically infeasible. But these companies still need to find effective material handling solutions that increase productivity as they face more pressure to meet demands driven by a strong e-commerce economy and mass customization.

These smaller companies don’t have to install pricey automated systems to increase throughput, nor do they have to sacrifice safety. They can opt for solutions that allow workers to load a pallet, container or cart onto a device that lifts, tilts or rotates the material toward them, says Jim Galante, director of business development at Southworth Products Corp., a maker of ergonomic material handling lifting and positioning equipment.

The Right Pick: Strategies for Handling Short Orders

Taking the pain out of the picking process with cost-effective material handling solutions.

Think about all the different types of beverages available today. Of course, diet and caffeine-free sodas have been on the market for years. But now consumers can find zero-calorie drinks made with stevia, drinks made with coconut water, more exotic flavors, and different size options. A single serving size can range from 7.5-ounce soda cans to 20-ounce water and sports drink bottles.

The food and beverage sector is just one example of an industry expanding its offerings to meet a diverse range of customer demands. This phenomenon, often referred to as SKU proliferation, has a significant impact on material handling operations. Pallets with different product mixes can wreak havoc on stocking and picking operations.

Ergonomics Check-Up: Solve Ergonomic Issues With a Holistic Approach

Ergonomics Check-Up: Solve Ergonomic Issues With a Holistic Approach

It’s easy to settle for the quick fix when a painful situation arises. Facility managers should resist this temptation when they notice injury trends in the workplace, says Jim Galante, director of business development at Southworth Products Corp, a maker of ergonomic material handling equipment.

“They want to do something quickly to show the employees that they’re making progress,” Galante says. “There’s the old argument that even though I didn’t fix 100% of the problem, if I fix 30% of it, it’s 30% better than it was. That’s like cutting back from two packs of cigarettes a day to a pack-and-half because it’ll be 30% better for your health.”

A Smarter Approach to Material Handling

A Smarter Approach to Material Handling

Today's "smart" plants leverage the power of IoT, automation, and additive manufacturing to increase efficiencies and output. In this high-tech environment, it's easy to forget about basic lean principles that can reduce or eliminate wasted movements and increase safety.

One of the key areas that manufacturers often overlook is material handling.

"Work cells and workstations are compact, tight areas, and they need to be for operator efficiency, convenience, and effective utilization of costly floor space," says Jim Galante, director of business development at Southworth Products Corp, a maker of ergonomic material handling and positioning equipment.

Economics of Ergonomic Material Handling

Economics of Ergonomic Material Handling

Good ergonomics is not just a nice thing to do, it is a must-do, based on its economic value. Many claims are for injuries that are the result of accumulated trauma, rather than from a single event, including sprains, strains, tendonitis, and lower back pain. The injuries derive from actions that create excessive or repeated stress on backs, shoulders, elbows, wrists, ankles, and hands. Costs of lost-time injuries vary, but using a conservative average of $25,000 per incident, preventing a single lost-time injury can save more than enough to pay for ergonomic equipment. In addition, ergonomic improvements can eliminate wasted motion – a core lean manufacturing tenet and a precursor to increased productivity.

The Risks of Unloading

Unloading Risk: The Benefits of Forklift-Free Plants

Imagine a forklift-free plant floor where unmanned carts deliver parts to an assembly line. It's a scenario that's becoming a reality in at least a few plants throughout North America. Last year, NED mentioned John Deere's plans to introduce automated guided vehicles to deliver parts and materials throughout its Horicon, Wis., plant.

Not every plant has the budget to implement such high-tech, automated solutions. But any technology that can decrease forklift traffic helps plants improve material flow and increase safety, says Jim Galante, director of business development at Southworth Products Corp., a maker of ergonomic material handling equipment.

Prepare for Robots

Position for Humans, Prepare for Robots

This year’s ProMat taught us that automation may be inevitable, but for many, unaffordable. So the key is to buy positioning equipment for both human and robot workers.

A little while back, we spoke with the CEO of Southworth Products, Brian McNamara, about how every company needs to develop its own pathway to automating its material handling processes, as every operation’s budget and needs are different.

The main takeaway is that most companies should formulate a semi-automatic plan, one that mixes the best of human intelligence and dexterity and robots’ virtues of reliability and repetition.

The Aging Workforce

Within Hand's Reach: Solutions for an Aging Workforce

Material handling tables and lifts can help manufacturers meet the needs of the changing workforce by increasing productivity, efficiency, and safety.

Creaking knees, bad backs and beer bellies aren't the type of attributes most organizations seek in material handling or manufacturing personnel. The reality, though, is that companies may not have many options.

Materials Handling Automation

Even If You Can't Automate You Can Still Do Something!

Back when Brian McNamara started working at Southworth Products in 1981, the material handling equipment maker's current president and CEO saw the beginnings of a brave, new automated world on the factory floor. Sure, there weren't artificially intelligent self-driving lift trucks delivering pallets to collaborative robots, but there were AGVs chugging along magnetic tape pathways and welding robots.

"We get lost in if we automate or we don't," McNamara says. "It's not black or white."

That gray area is how the Maine-based manufacturer has stayed relevant in a world of servos, semi-conductors and artificial intelligence despite engineering with springs, steel, and hydraulics.

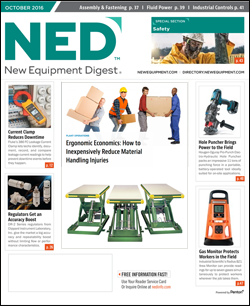

Ergonomic Economics

How to Inexpensively Reduce Material Handling Injuries

Material handling injuries are costing small companies billions of dollars a year. What's worse is that many of these injuries seem to be preventable. Here's how to prevent them in your workplace.

Southworth's Jim Galante shares discusses simple, cost-effective ways to reduce worker injuries and their associated costs in a discussion with the editors of New Equipment Digest.